What is Stock Management?

Stock Management is one of the important areas under the responsibility of the personnel responsible for manufacturing, due to its task undertaken in order to meet the need at the desired time. In other words, the stocking cost has a great value among the materials that include the product costs, and the production can be made in accordance with the production plan.

Stock management includes the planning and control of raw materials, semi-raw materials and other materials, logistics activities (loading - unloading - transportation), keeping the process of the material in the company under control, stocking, shipping materials or finished products.

Purpose and Scope of Stock Control

The main purpose of stock control is; It is the execution of the production without interruption by keeping the raw materials, materials, spare parts and other necessity items in the enterprise neither less nor more, but sufficient amount. In other words, the purpose of stock control is to find answers to two seemingly simple questions about "when" and "how much" the materials and spare parts required for production will be supplied. In stock control, monitoring stock movements, keeping necessary statistics, counting and physical control and determination of inactive and dead stocks should also be considered within the stock control function.

Expected objectives of stock control; To provide the material requirement at the desired time, in the desired amount, in the desired place and in the desired quality. To achieve the goal in stock control; Determining which materials will be stocked and deciding how much stock will be made, but during the making of these stock control determinations; It is necessary to meet the requirements in production plans at a sufficient level, to allow working capital to keep stocks, ordering times, order lead times, superiority of purchases to be made in large batches, appropriate and sufficient storage facilities, order and holding costs principles.

A correct stock management and stock control can only be possible with the establishment and operation of the necessary system to reduce costs and keep production plans running smoothly. The level of raw materials, semi-finished products and spare parts stock varies according to the type of production.

Stock Control Methods

The main purpose of the methods developed for stock control; It is the determination of the stock levels that will provide the materials needed by the enterprises when needed, in the desired amount and at the optimum capital cost. Stock control methods;

Visual Control Method

Double Box Method Minimum-Maximum Method

ABC Stock Management

Economic Order Quantity Model (ESM)

Material Requirements Planning (MRP)

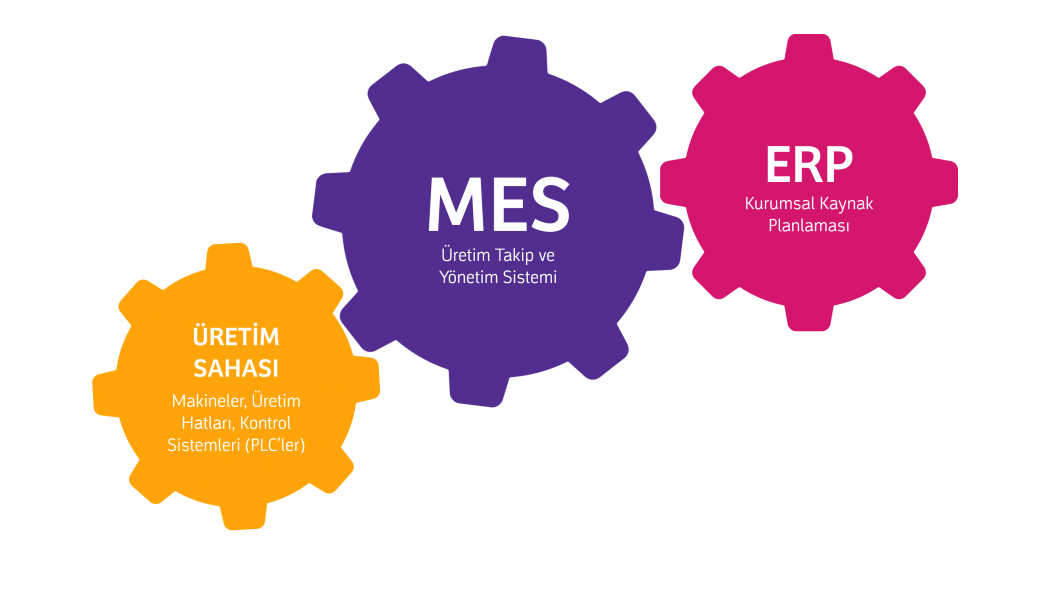

Enterprise Resource Planning

Just in Time Procurement and Card (Kanban) System

stocks can be controlled and managed with different methods.